Wirewound Resistor

A wirewound resistor is a passive electrical component that restricts the flow of current in a circuit using a conductive wire wrapped around an insulating core.

Wirewound resistors rely on the principle that all conducting wires have some resistance. A resistor can be made from a wire alone. The shorter and thicker a wire is, the lower the total resistance will be. The longer and thinner the wire, the greater the total resistance.

What is a Wirewound Resistor?

A wirewound resistor is a type of electrical resistor that features a conductive wire wound around a non-conductive core. The core must be an insulator or the resistor will function as an inductor.

Wirewound resistors tend to feature more inductance than other types of resistors due to their construction method, which is almost identical that of an inductor. The primary difference is the resistor’s use of an insulating core. However, wirewound resistors with a helical wrapping pattern will still feature significant parasitic inductance. This inductance can have a pronounced effect in high frequency applications. The inductance can be controlled using special wiring techniques that cancel out the inductive magnetic field generated by the current in the wires.

Wirewound resistors take advantage of the fact that every conducting wire has some resistance. The resistance of a wire can be increased by making it longer or thinner. However the power rating is also proportional to the wire thickness. If we want a resistor with high resistance and power or voltage rating than we will need it to be longer. This means that the resistor will be larger in size and cost more as well.

Wirewound resistors are most commonly used in industrial and high power applications. They have been very popular for decades, and there is good reason for this. They can have very good tolerances; 0.005% is common. Long term stability is also excellent because the material design is very stable. They don’t have the internal stress issues faced by carbon composition resistors. They are stable over a long period of time. Finally, they have a low temperature coefficient, meaning that they are stable at varying temperatures.

Wirewound Resistor Inductance

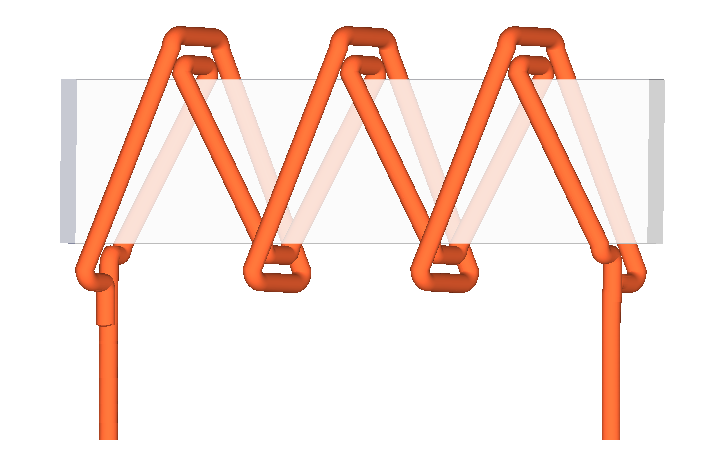

The basic method of construction of a wirewound resistor uses a simple helical winding. By wrapping each coil sequentially, the resistor resembles an inductor. The cause of the inductance is a magnetic field that is induced by the current in the coiled wire. The greater the number of coils, the larger the resulting magnetic field will be. This means that the inductance would be very high, particularly for components with many coils (as we would want for greater resistance).

The main difference is that the resistor uses an insulating core to dampen the inductive effects, while an inductor uses a magnetic core to boost the inductive effect.

There is a better way to reduce the inductance: you can wind the resistor in such a way as to reduce or eliminate the magnetic field. You can see these examples below:

Below the simple helical winding is a thin former winding pattern. This minimizes the inductance while still only requiring a single pass of wire.

For even lower inductance, we can use a parallel winding pattern where the magnetic field from one set of windings cancels out the magnetic field from the other set. The bifilar coil is a common example of this, featuring two closely spaced parallel helical windings.

An even lower inductance can be achieved by using an Ayrton-Perry winding, which combines thin former geometry with bifilar double winding.

Ayrton-Perry Winding

Non-inductive resistors with Ayrton-Perry winding patterns are often used in military and industrial applications.

Resistors made with these specialized windings are commonly referred to as ‘non-inductive’ and are often suitable for high frequency applications.

Manufacturing these resistors is more difficult than those with simple helical windings. Non-inductive resistors therefore they cost more than resistors with helical windings and are much less common.

Wirewound vs. Film Resistor

Film resistors generally have superior qualities when compared with wirewound resistors, in particular the simple/inductive type. This is especially true in high frequency applications, where parasitic inductance would be increased.

In general, film resistors are superior in terms of cost, in high frequency applications, and where size is a factor. Wirewound resistors are best when accuracy is the most important consideration.